Ceramic metallization

Ceramic metallization

Ceramic metallization

Ceramic metallization

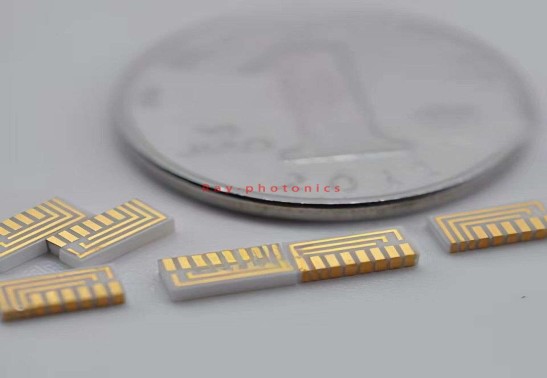

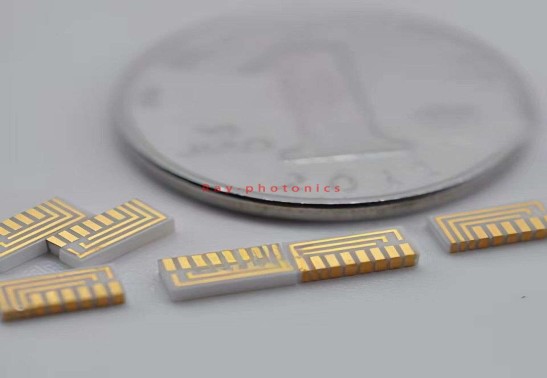

1. Customized design: Support 2.5μm~10μm metal plating, thin film resistor forming.

2. Features:

Alumina purity ≥99.5% and aluminum nitride purity ≥99.9%, high-purity substrate can achieve low loss at high frequency; high-quality alumina and nitride with good thermal conductivity, strength and insulation Aluminum plate.

3. Material properties:

Item Unit Measurement

Thermal conductivity W/m・K 29 ~ 320

Thermal expansion coefficient X10-6/K 40~300°C&40~500°C&40~800°C

Q value

> 10000

Dielectric constant er 9.8 @10GHz10.3 @1MHz

4. Uses:

Input and output of high-frequency devices, substrates of optical fiber transmitters, optical communication devices are used as power-off carriers, thermal conductive substrates, and circuit substrates for various optical communication devices.

5. Volume resistivity: 25°C...>1014Ω·cm; 300°C...>1 014Ω·cm;

500°C・・・>1010Ω・cm;700°C・・・>107Ω·cm;

6. Metallization form: ceramic white sheet, single-sided metallization, double-sided metallization, three-sided metallization, four-sided metallization.

7. Film composition: Ni, Cr, Ti, TiW, NiV, NiCr, AL, Cu, Pt, Au, etc.

♦Design Guidelines

•Material: alumina content > 99.5%; aluminum nitride content > 99.9%

•Basic size: 1 mm*1 mm~50mm*50mm

• Substrate thickness: 0. 2mm~1.5mm

• Coarse grinding: 0. 25μm Ra Max

• Mirror Matte: 0. 025μm Ra Max

GET IN TOUCH