Metallized Fiber

Metallized Fiber

• Singlemode, multimode, or polarization maintaining fibers

• Easy to solder

• Cleaved enfaces available

• Unplated (masked) ends available

• Mid-span plating available

• Designed to meet Telcordia requirements

• Large volume manufacturing capacity

• Custom configurations available

Fiber Type | Singlemode, PANDA PM, Polyimide Coated, Bend Insensitive, Teflon Coated, Ribbon Fibers or Custom |

Ferrule Type | Kovar, Zirconia, Stainless Steel 304L, Gold Metallized |

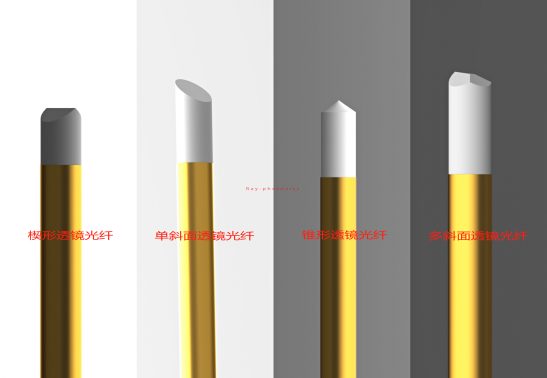

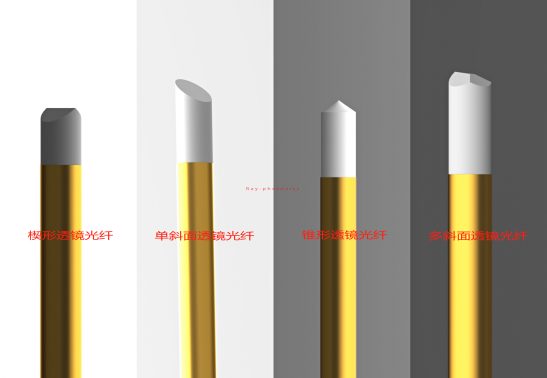

Fiber Tip | Flat, Angle Polished, or Lensed, & AR Coatings |

Fiber Jacket | 900µm Loose Tube, Tight Buffer, Teflon, Stainless Steel Armored |

AR Coating | Reflectivity: ≤ 0.25%, 375nm-1650nm Overspray: 0.8mm |

Bending Radius | 0.5in minimum for 900µm jacket |

Metallization | Overspray on Polyimide Coating Allowed |

Temperature Range | Storage: -55°C to 175°C |

Visual Inspection | No visible chip or scratch under 400X magnification |

Insertion Loss | < 0.1 dB |

Return Loss | > 55 dB for UPC, > 65 dB for APC |

Connector Type | Seiko or equivalent |

Epoxy | Low outgassing, High Reliability |

GET IN TOUCH